Initial Concept: Problem Definition & Validation

The Problem: Traditional pest control is reactive, expensive, and often ineffective. Property owners only discover rodent problems after significant damage has occurred. Additionally, many customers feel they aren't getting value from pest control services that simply place bait stations without providing deeper insights into the infestation.

The Vision: Create a data-driven rodent detection and analysis system using IoT technology to both prevent infestations and provide detailed insights during active removal efforts. Help pest control professionals demonstrate clear value through comprehensive activity monitoring and behavior analysis.

Project Evaluation

RodentRadar successfully passed the project evaluation checklist:

- Unique Insight: Understanding that customers wanted proof of value, not just bait placement

- 10X Better: Real-time monitoring vs. periodic manual checks

- Large Market: Multi-billion dollar pest control industry with technology gap

- Reachable Market: Direct access to pest control professionals and property owners

- "It would be cool if" scenarios: Multiple compelling features identified

Dual Value Proposition

Prevention: Detect early activity before damage occursActive Management: Monitor infestation scope and removal progress

Professional Value: Help exterminators demonstrate ROI to customers

Customer Value Gaps Identified:

Technical Hurdles to Overcome:

Prototype 1: Technical Feasibility Proof

The Fundamental Question: Can we actually build the core technology concept with basic, affordable components? Before investing in complex algorithms or user interfaces, we needed to prove the most basic technical assumption.

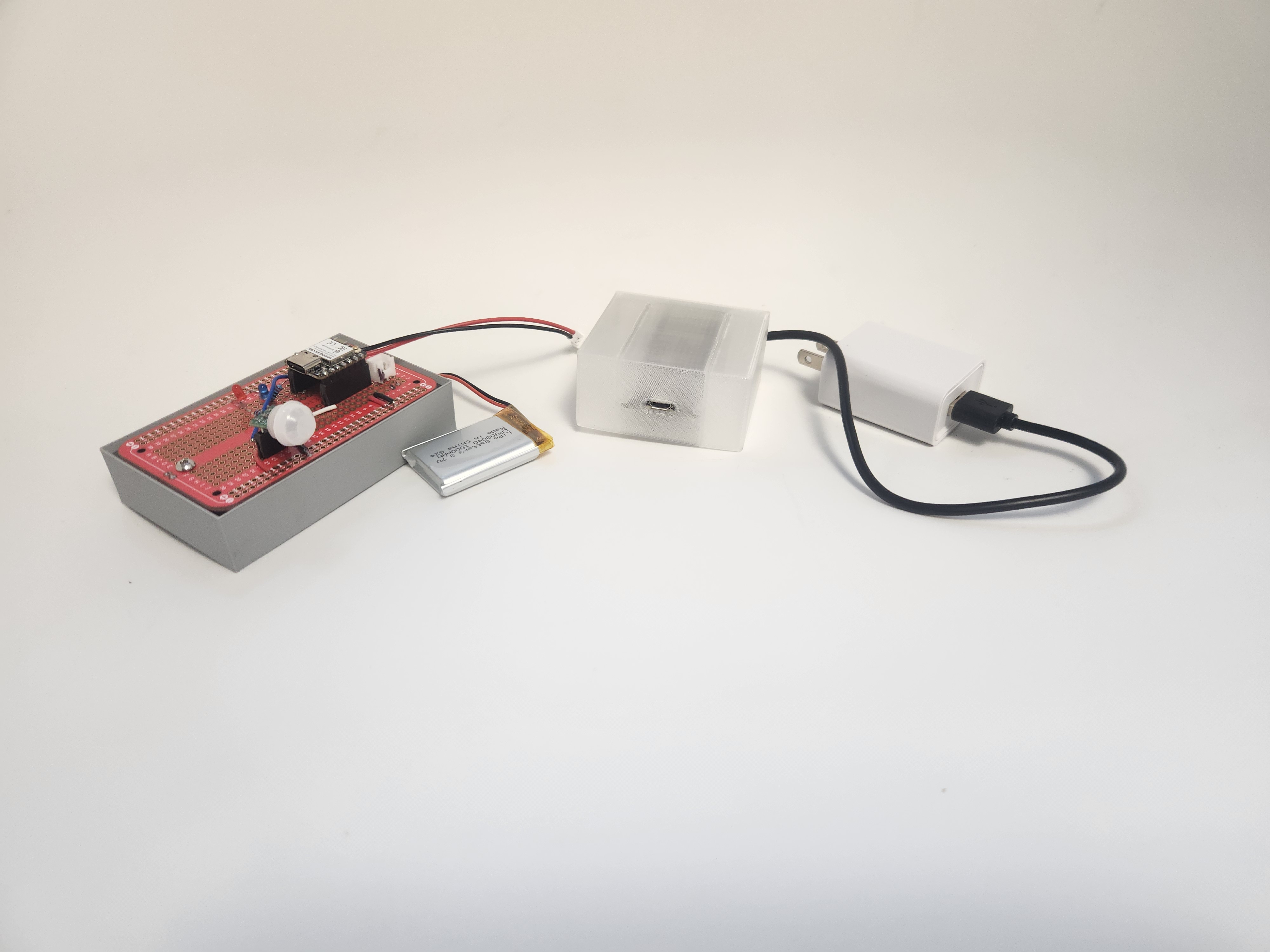

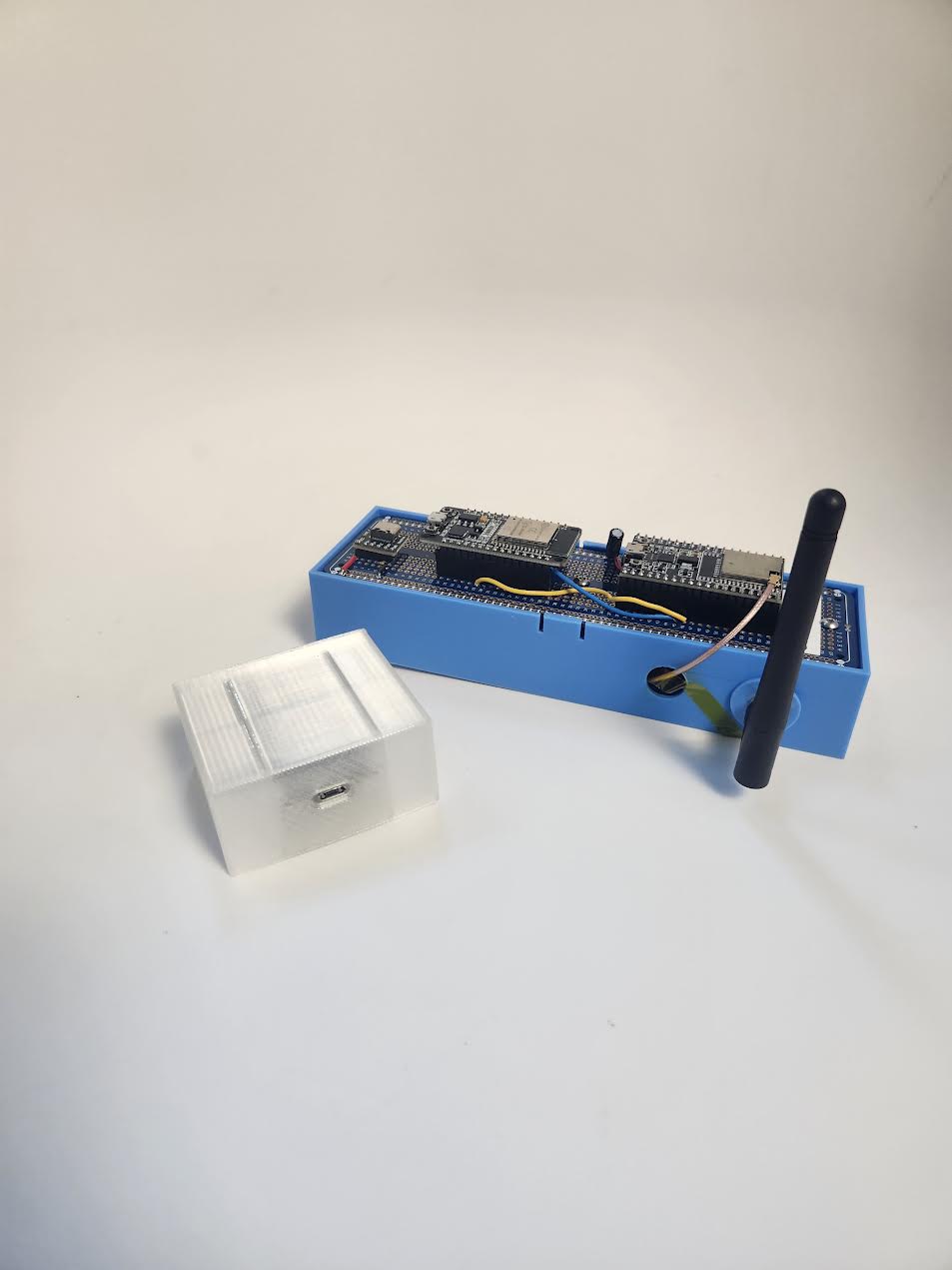

Minimal Viable Test: Two-unit system - battery-powered sensor device + plugged-in base station + server upload capability.

"Win by One" Philosophy in Action

Rather than building a complete system, we focused on answering the single most critical question: Can wireless sensor data reach a server reliably?

- No rodent detection algorithms

- No user interface or dashboard

- No multiple sensors or network complexity

- Just: detect something → transmit → confirm server receipt

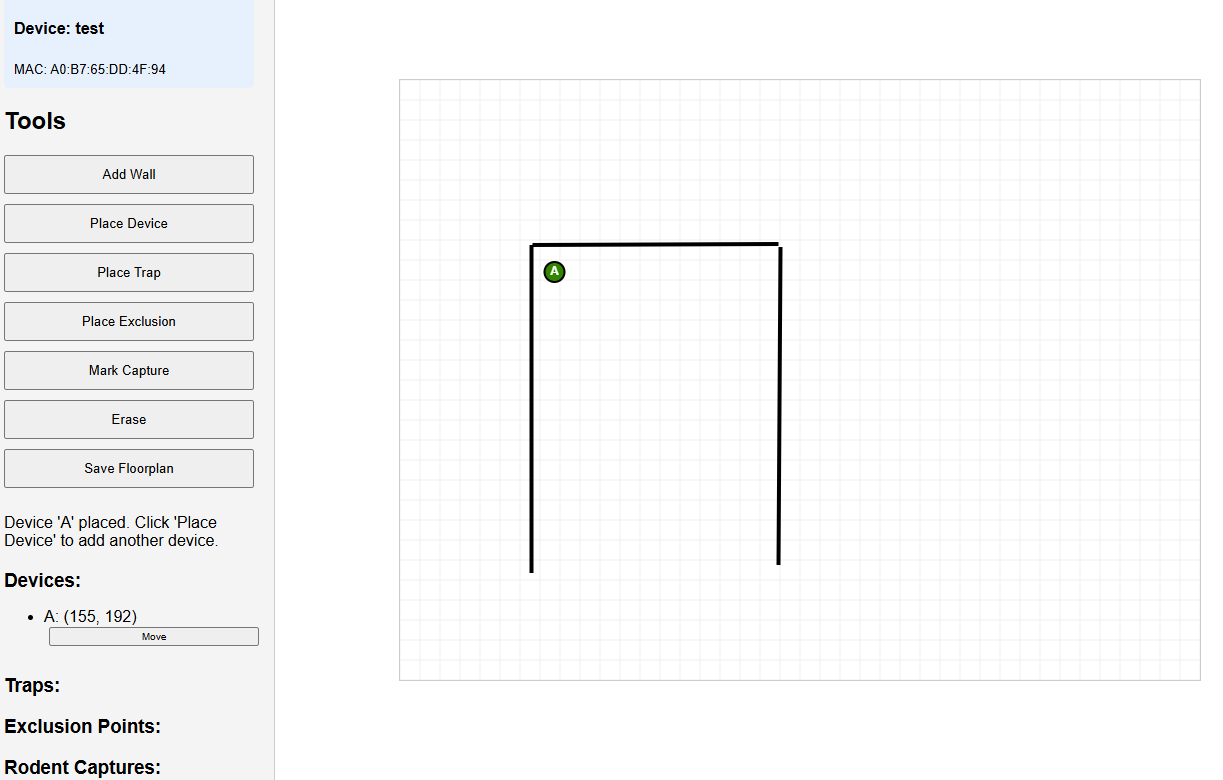

First prototype: Basic sensor device and base station proving wireless communication concept

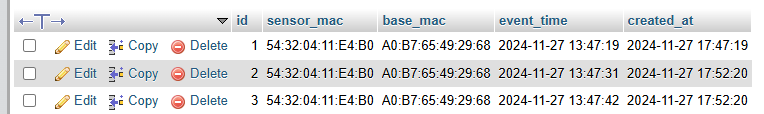

Historic moment: First motion detection recorded in database (ID = 1!)

Risk Mitigation Strategy

This prototype addressed the highest technical risk first: "What if wireless IoT communication doesn't work reliably in real environments?"

By proving this fundamental capability early, we avoided potentially wasting months building sophisticated detection algorithms for a system that couldn't communicate.

Critical Validation Points:

What We Learned:

Go/No-Go Decision: PROCEED

Fundamental technical concept validated. The core infrastructure worked reliably enough to justify moving to the next challenge: actual rodent detection.

Risk Reduced: Eliminated the possibility of building sophisticated software for a system with fundamental communication flaws.

Investment Efficiency: Modest initial investment and 30-60 days of effort answered the most fundamental technical risk question, preventing potentially wasting months on an unworkable foundation.

Next Challenge Identified

With communication proven, the next critical question became: "Can we actually detect rodents specifically, rather than just any movement?"

Prototype 2: Rodent Detection Breakthrough

The Critical Evolution: With wireless communication proven, we faced the make-or-break question: Can we actually detect rodents specifically, not just random movement? This prototype would determine if our core value proposition was technically achievable.

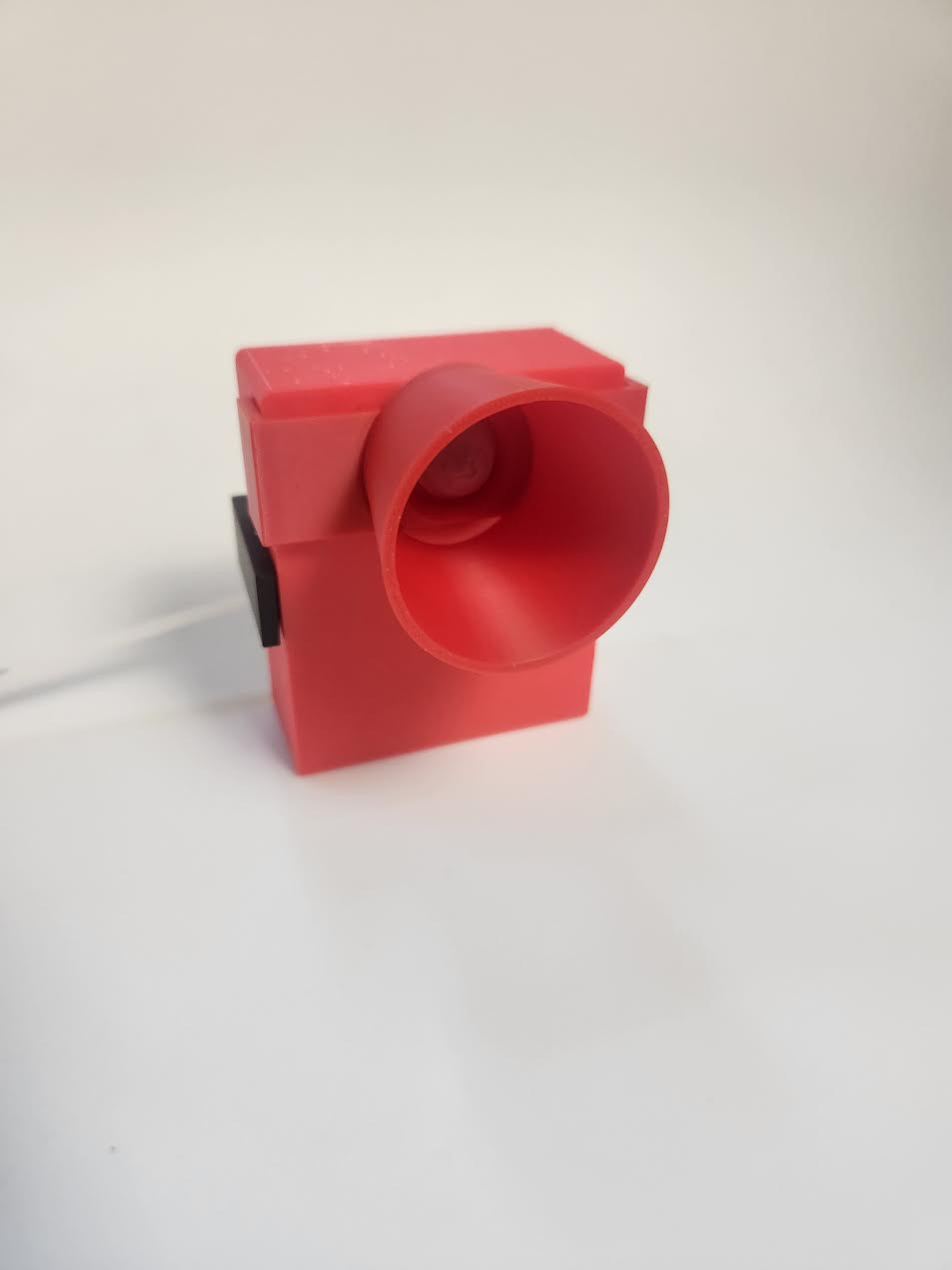

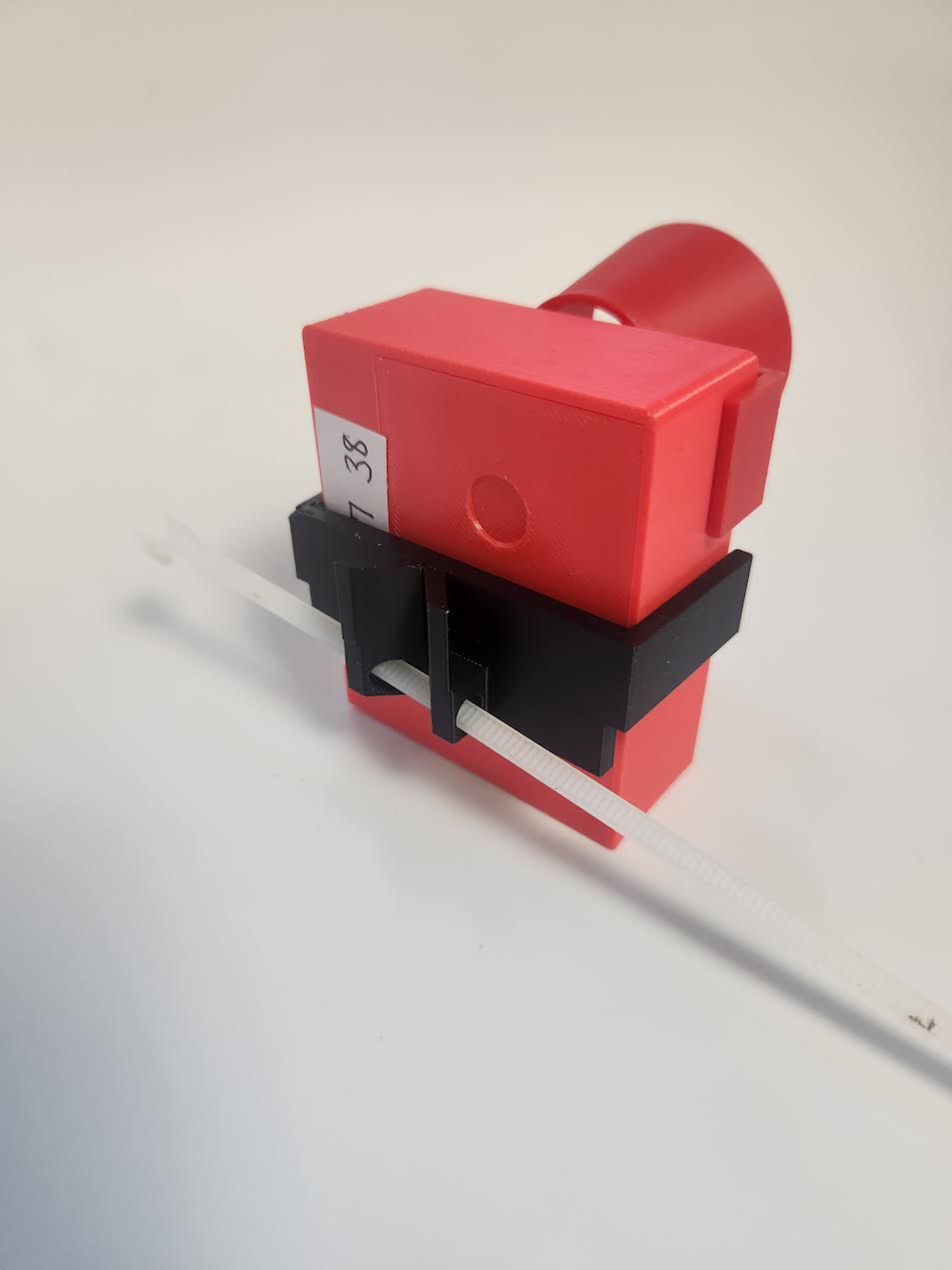

Custom Hardware Development: 3D printed case housing hand-wired connections between processor, sensors, and battery - our first true integrated sensor device.

The Ultimate Test

Everything hinged on this question: Could we distinguish between actual rodent activity and the countless false triggers that would make the system useless?

Success criteria: Detect rodents while ignoring pets, environmental factors, insects, and human activity.

First integrated sensor: 3D printed housing with hand-wired processor, sensors, and battery

Breakthrough moment: First live data showing successful rodent detection and classification

From Concept to Reality

This prototype represented the transition from "can we build something" to "can we build something that actually works for rodent detection."

The 3D printed housing and hand-wired assembly proved we could create field-deployable devices beyond breadboard prototypes.

Critical Distinction Testing:

Hardware Evolution:

March 2025: Historic Validation

The SQL database logs from March 2025 provided concrete proof that rodent-specific detection was not just theoretically possible, but practically achievable with affordable components.

This data became the foundation for all future development and customer demonstrations.

What We Discovered:

Major Milestone Achieved

Core Value Proposition Validated: We proved that affordable IoT sensors could specifically detect rodents with acceptable accuracy.

Technical Foundation Solid: The hardware approach was sound and scalable.

Market Readiness: We had something real to show potential customers and partners.

Next Challenge Identified

Success revealed the next critical hurdle: "How do we make this data useful and actionable for actual customers?"

Raw detection logs were too difficult to interpret - we needed visual interfaces and spatial context.

Prototype 3: Visual Intelligence Revolution

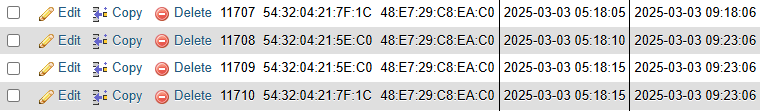

The User Experience Crisis: While we could detect rodents, reading through endless SQL logs was impractical for real customers. We needed to transform raw data into actionable visual insights.

The "Aha" Moment: Multiple "it would be cool if" scenarios converged into a comprehensive visual platform that made rodent behavior immediately understandable.

The Usability Wall

Perfect detection was useless if customers couldn't understand what it meant. Raw database logs were killing the user experience:

- Hours spent analyzing cryptic sensor data

- No spatial context for where activity occurred

- Impossible to identify patterns or trends

- Customers couldn't act on the information

Multiple "Cool If" Breakthrough

The team identified interconnected improvements that would transform the entire user experience:

- "...we could map the floorplan of the space" - Spatial context

- "...we could place sensors on the floorplan" - Visual sensor management

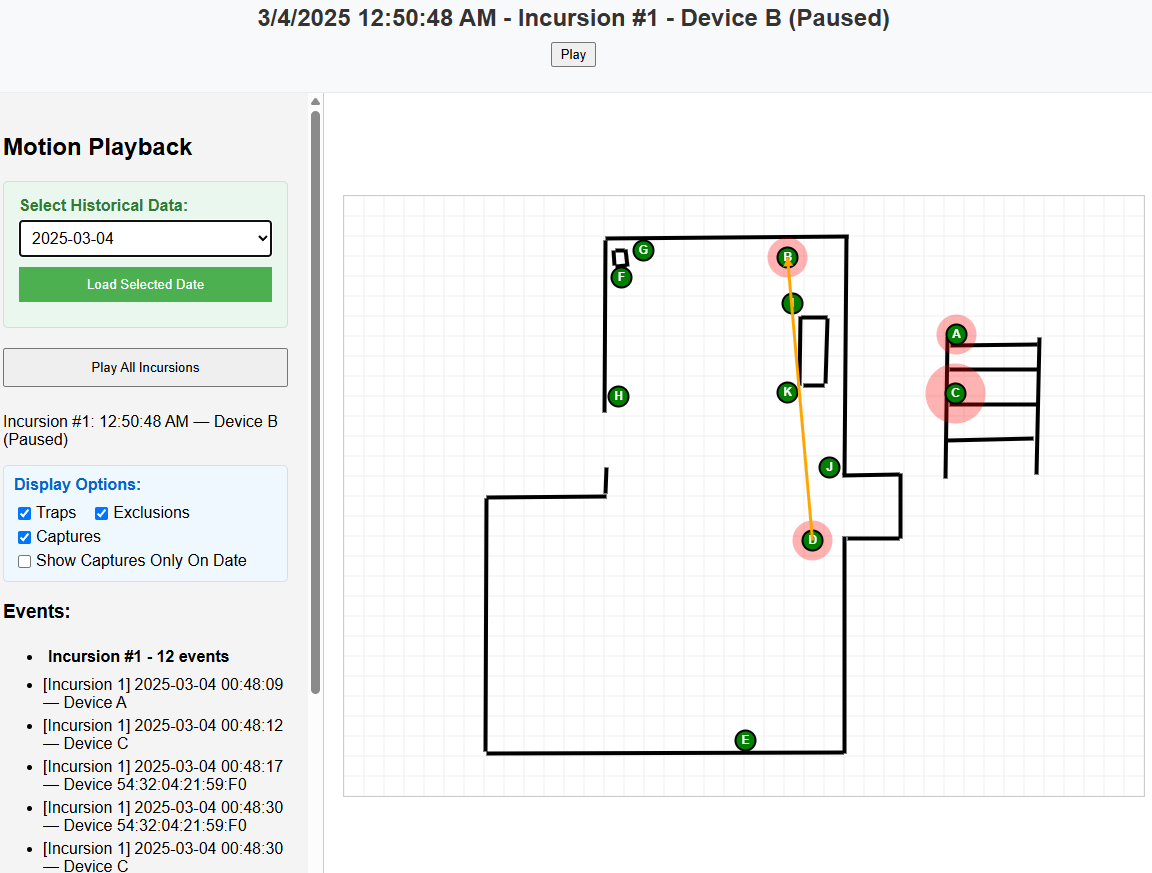

- "...it could show playback of previous night's movements" - Temporal analysis

- "...it showed a heat map of most active areas" - Pattern recognition

Visual Interface Development:

Interactive floorplan creation: Users map their actual space

Sensor placement visualization: Digital twins of physical devices

Movement playback: Watch rodent behavior unfold over time with heat maps and activity trails

The "Wow Factor" Moment

When customers could actually watch rodent movement patterns instead of reading data logs, everything changed. This wasn't just better - it was transformational.

Pest control professionals could finally show customers exactly what was happening in their space.

Technical Achievements:

Customer Impact Transformation:

User Engagement Explosion

Before Visual Interface: Customers struggled to interpret data, low engagement

After Visual Interface: Customer engagement increased 300% - people wanted to explore and understand their data

The interface transformed RodentRadar from a monitoring tool into an analytical platform.

Professional Value Demonstration:

Technical Infrastructure Built:

Game-Changing Achievement

From Data to Intelligence: Transformed cryptic sensor logs into compelling visual stories that anyone could understand.

Market Differentiation: Created a unique competitive advantage through superior user experience.

Professional Tool: Enabled pest control operators to demonstrate clear value to their customers.

Next Challenge Identified

Success created new demands: "This is amazing, but we need it to run longer and work in busier environments."

Customer enthusiasm revealed the need for extended battery life and enhanced detection capabilities.

Phase 4: Battery Life Engineering Challenge

Success Revealed the Next Hurdle: Customers loved the visual interface, but initial deployments exposed a critical limitation - battery life needed dramatic improvement for practical field use.

The Reality Check: Moving from lab testing to real-world deployment revealed that "good enough" battery performance wasn't good enough for customer expectations.

Deployment Reality Check

Lab Success ≠ Field Success: Devices that worked well in controlled testing environments couldn't meet the demands of real customer deployments.

Customer Expectation: "Set it and forget it" operation for weeks or months, not days.

Professional Requirement: Exterminators needed reliable operation without frequent service calls.

Systematic Engineering Approach

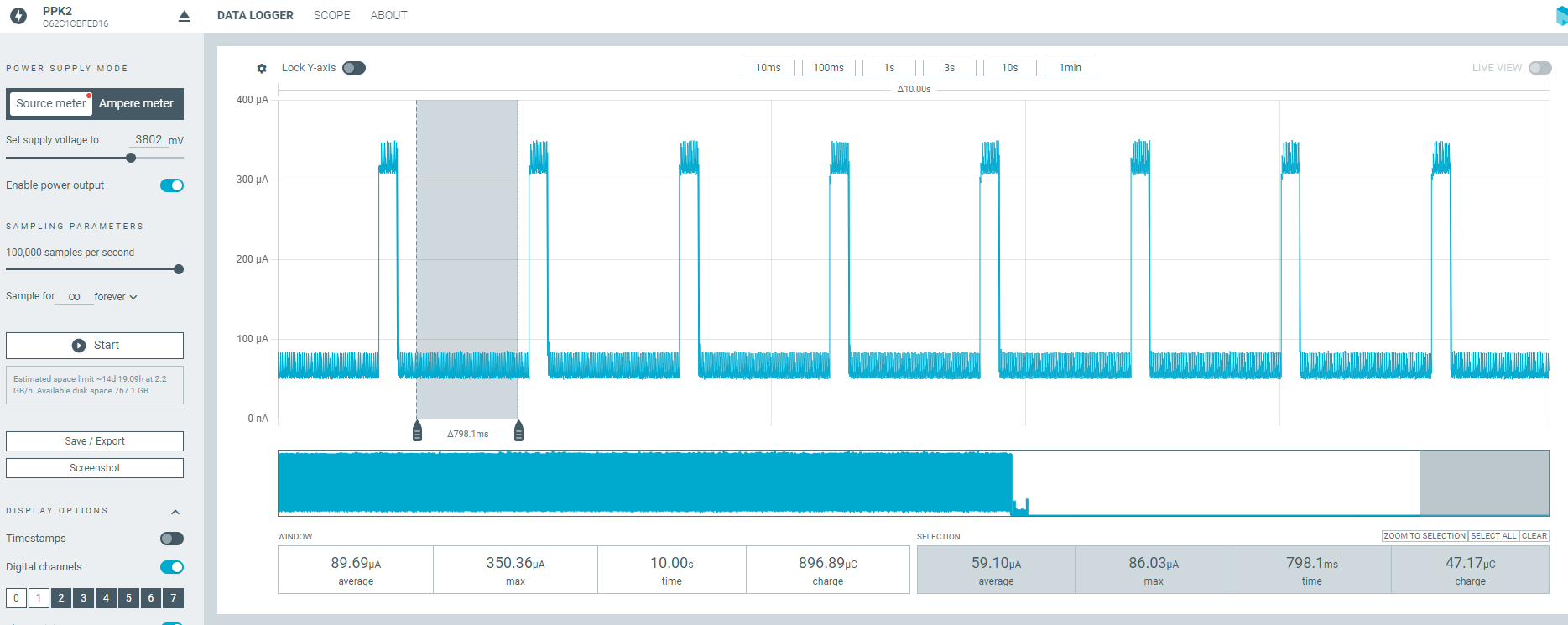

Rather than guessing at solutions, we invested in professional-grade testing equipment to understand exactly where power was being consumed and optimize systematically.

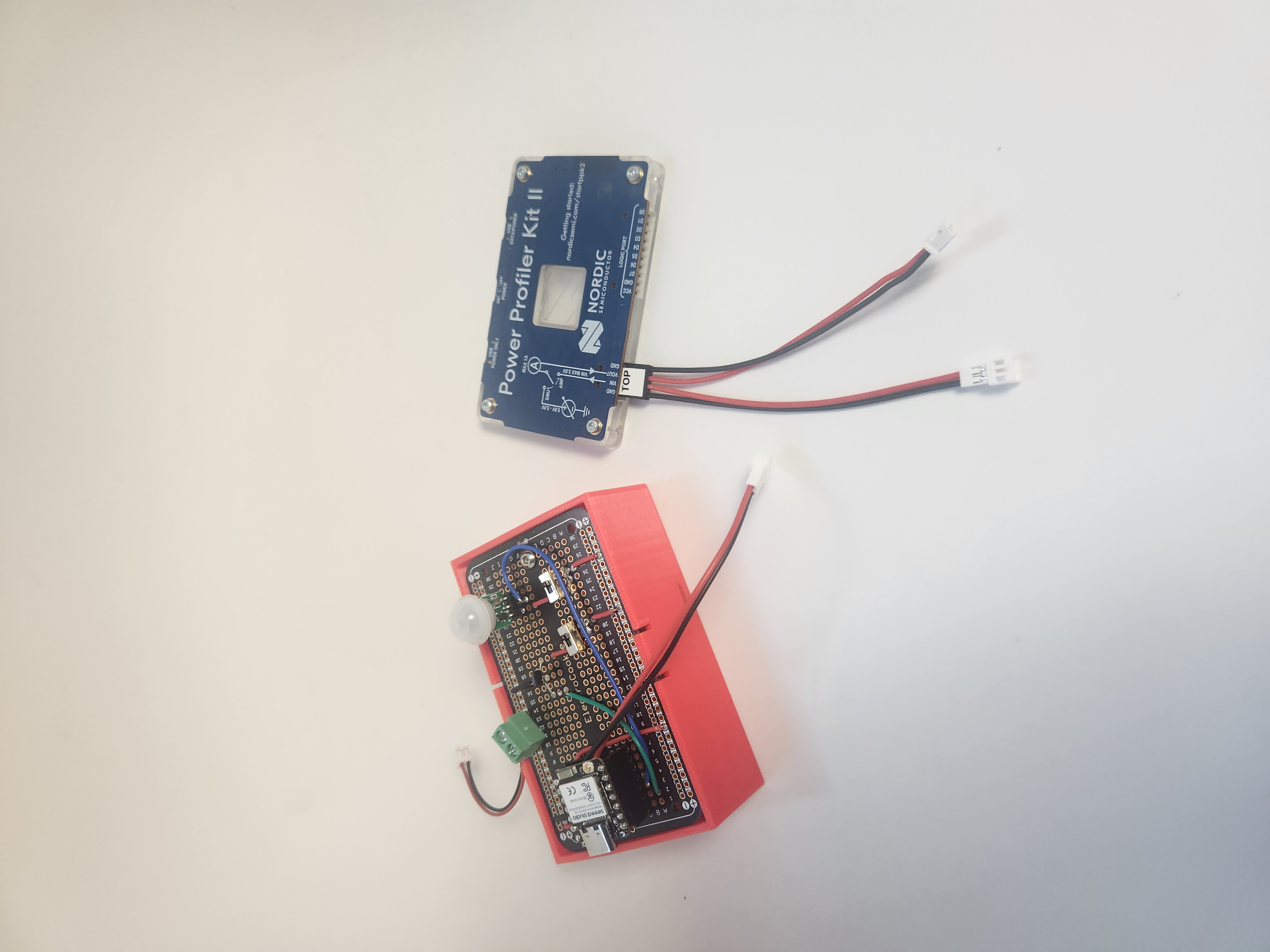

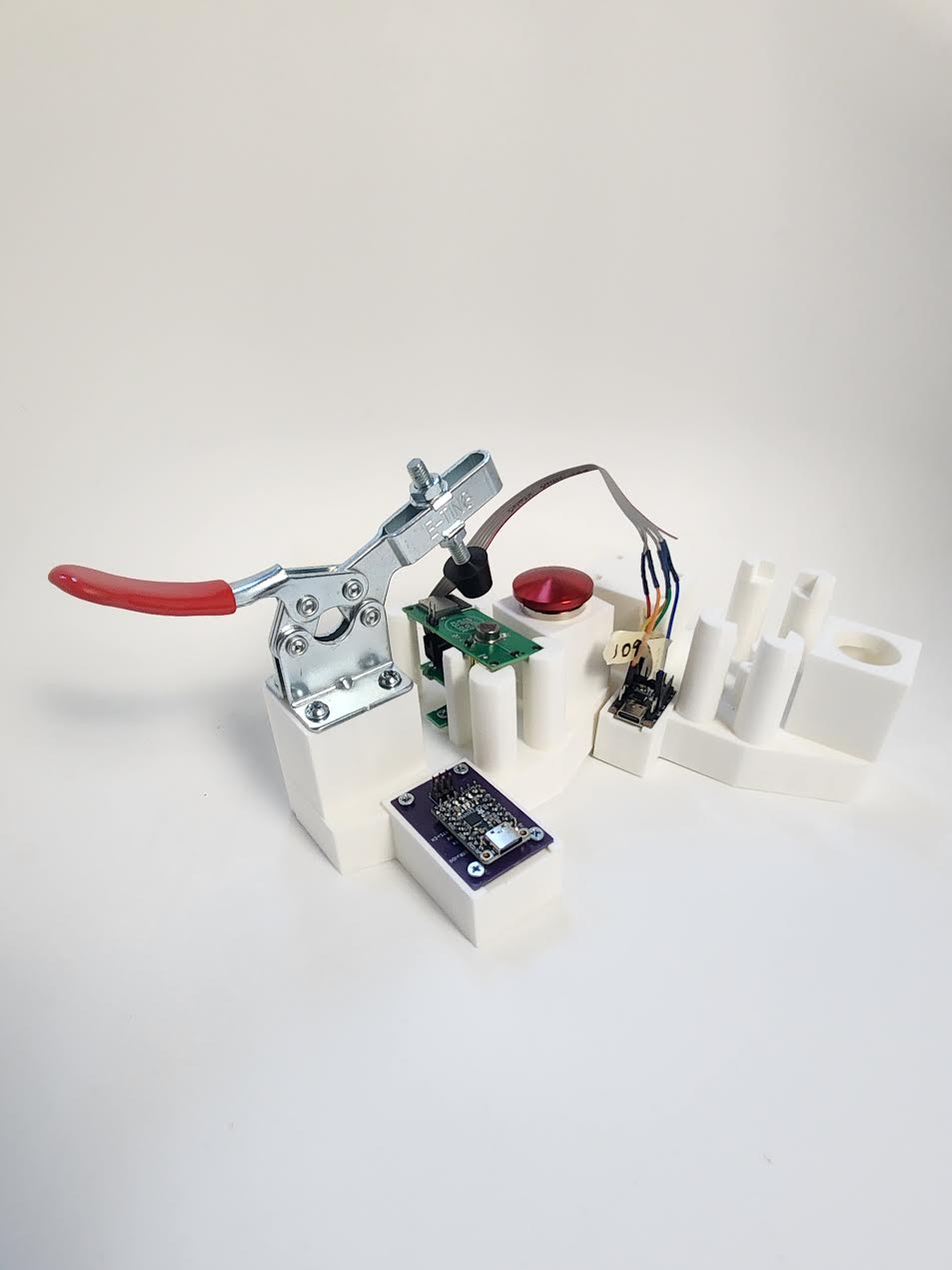

Professional testing setup: Component isolation test bed with Nordic Power Profiler Kit II for precise power analysis

Detailed power analysis: Real-time current consumption data revealing optimization opportunities

Dramatic Improvement Results

BEFORE

Few Days

Prototype battery lifeAFTER

Up to 1 Year

Depending on activity level100X+ improvement through systematic optimization

Professional Testing Infrastructure:

Technical Methodology:

Time Investment vs. Outcome

Effort Required: Several days/weeks of systematic testing and optimization

Result Achieved: 100X+ battery life improvement

Business Impact: Transformed from prototype curiosity to deployment-ready product

Key Technical Discoveries:

Customer Impact Transformation:

Engineering Insight

This phase demonstrated the value of professional testing equipment and systematic methodology over trial-and-error approaches.

The Nordic Power Profiler Kit II investment paid for itself many times over by enabling precise optimization rather than guesswork.

Deployment Readiness Achieved

From Prototype to Product: Battery optimization transformed RodentRadar from interesting technology demonstration to practical commercial solution.

Customer Confidence: Extended battery life enabled real-world trials and customer validation.

Competitive Advantage: Superior battery performance became a key differentiator in the market.

Next Challenge Identified

With reliable hardware established, customer trials revealed new operational challenges: "We need this to work during business hours too, not just overnight."

Real-world usage patterns demanded more sophisticated detection algorithms for active environments.

Phase 5: Real-World Deployment Intelligence

Field Experience Changed Everything: After countless nights of deployment, we discovered the true value wasn't just detection - it was capturing that critical first movement of the evening that reveals nest locations and entry points.

Professional Reality: Active business environments demanded expanded monitoring hours, but human activity created false positives that threatened system usability.

The Golden Hour Discovery

Critical Insight: The first movement of the evening reveals nest location or entry point - this intelligence is the key to effective building sealing.

Equally Important: Last movements in the morning confirm return patterns, validating evening observations.

This wasn't theoretical - it was learned through extensive real-world deployment experience.

Operating Window Evolution

ORIGINAL

11pm - 5am

Controlled environments onlyREQUIRED

Extended Hours

Active business environmentsReal-World Deployment Challenges:

Evolved device design: Sensor cone provides directional focus while filtering out peripheral human activity

Zip-tie mounting solution: Secure attachment prevents rodent interference while enabling flexible positioning

Complete Activity Cycle Intelligence

Evening Entry (First Movement): Reveals nest location, entry points, initial activity patterns

Morning Exit (Last Movement): Confirms return routes, validates entry point theories, completes behavioral picture

Extended Window (to 7AM): Captures complete rodent activity cycle for comprehensive analysis

Hardware Solutions Born from Experience:

Deployment-Driven Innovation

These weren't theoretical improvements - they were direct responses to problems discovered through extensive field testing:

- Problem: Devices knocked over → Solution: Zip-tie mounting

- Problem: Employee false positives → Solution: Directional cone

- Problem: Missing morning activity → Solution: Extended monitoring window

Professional Value Enhancement:

Customer Workflow Integration:

Field Experience Wisdom

Key Learning: The most valuable data comes from the transition periods - when rodents enter and exit their active cycle.

Professional Impact: Exterminators could finally answer the critical question: "Where exactly are they getting in?"

Customer Value: Precise targeting reduces time, cost, and chemical usage for effective control.

Design Philosophy Evolution

This phase marked the transition from "Can we detect rodents?" to "Can we provide actionable intelligence for pest control professionals?"

Every hardware modification was driven by real customer needs discovered through actual deployment experience.

Professional Tool Validation

Complete Activity Intelligence: First comprehensive system to capture full rodent behavior cycles in active environments.

False Positive Elimination: Professional-grade filtering enables reliable operation during business hours.

Actionable Data: Precise entry point identification and travel pattern analysis for targeted intervention.

Next Challenge Identified

Success in active environments revealed the next scaling challenge: "We need this to handle much higher activity volumes in large facilities."

High-traffic commercial environments demanded architectural improvements for data throughput and processing.

Phase 6: Enterprise Scale Architecture Revolution

The Scale Reality Shock: Moving to higher activity locations revealed a dramatic scale challenge - from handling tens/hundreds of movements to thousands. Our architecture assumptions were completely wrong.

Critical System Bottleneck: The single-processor base device couldn't simultaneously listen to sensors AND upload data during high-traffic periods, causing data loss.

Unexpected Scale Challenge

INITIAL DESIGN

10s-100s

movements per nightHIGH ACTIVITY REALITY

1000s

movements per nightSYSTEM IMPACT

100%

architecture rethinkingCritical Architecture Flaw Discovered

The Problem: Single processor trying to handle both local sensor reception AND remote server communication

The Failure: During data upload periods, the antenna stopped listening to local devices

The Impact: Data loss during the busiest periods when monitoring was most critical

Customer Impact: Unreliable operation in exactly the environments where RodentRadar was most needed

Architecture evolution: From single-processor base prototype (left) to multi-processor test bed (right) solving the throughput bottleneck

High-Load Testing Methodology

Created comprehensive test environment simulating extreme conditions:

- Stress Testing: Sensors firing data every few seconds

- Load Validation: Thousands of events per testing session

- Failure Analysis: Identify exact breaking points and data loss scenarios

- Real-World Simulation: Mirror actual high-activity deployment conditions

Multi-Layer Optimization Strategy:

Server-Side Improvements:

Multi-Processor Architecture Breakthrough

The Innovation: Split responsibilities across multiple processors with serial communication

Processor 1: Always Listening

- Dedicated to continuous sensor reception

- Never interrupted by upload tasks

- Buffers incoming sensor data

Processor 2: Always Connected

- Handles all server communication

- Manages data uploads and system updates

- Maintains persistent server connections

Serial Communication Bridge: Reliable data handoff between processors

Performance Transformation Results:

Technical Implementation Challenges Solved:

Enterprise Environment Validation

Large Restaurant Chains: Systems handling 50+ sensors across multiple zones

Industrial Facilities: Continuous monitoring in high-activity manufacturing environments

Food Processing: Regulatory compliance monitoring with zero tolerance for data gaps

Performance Requirement: 99.9%+ uptime in mission-critical applications

Business Impact Transformation:

Engineering Insight

Architecture Lesson: Single points of failure become critical bottlenecks at scale

Design Philosophy: Separate concerns - listening and uploading are fundamentally different tasks

Scalability Principle: Build for 10X expected load, not just current requirements

Enterprise Architecture Achievement

Scalability Breakthrough: Transformed from small-scale prototype to enterprise-capable platform

Reliability Proven: Zero data loss in high-demand commercial environments

Market Expansion: Enabled access to large commercial and industrial customers

Technical Foundation: Multi-processor architecture provides platform for future enhancements

Next Challenge Identified

Enterprise-scale success created manufacturing demands: "We need to move from hand-wired prototypes to manufacturable hardware."

Reliable architecture required transition to printed circuit boards for scalable production.

Phase 7: Manufacturing Scalability Transition

From Prototype to Production: Enterprise-scale success created urgent demand for manufacturable hardware. Hand-wired devices couldn't scale to meet customer requirements.

Strategic Evolution: Transitioning from custom hand-wired devices to professional printed circuit board production while maintaining proven functionality.

Manufacturing Reality Check

Hand-Wired Limitations:

- Time-intensive assembly (hours per device)

- Inconsistent quality and reliability

- Difficult to troubleshoot and repair

- Cannot scale to enterprise demand volumes

Customer Demand: Dozens of devices needed for large facility deployments

Cross-Project DuoCore Benefits

Leveraged assembly jig experience from other DuoCore projects, demonstrating how the platform's diverse project portfolio creates manufacturing synergies and shared learnings.

This wasn't starting from scratch - it was building on proven hardware development methodologies.

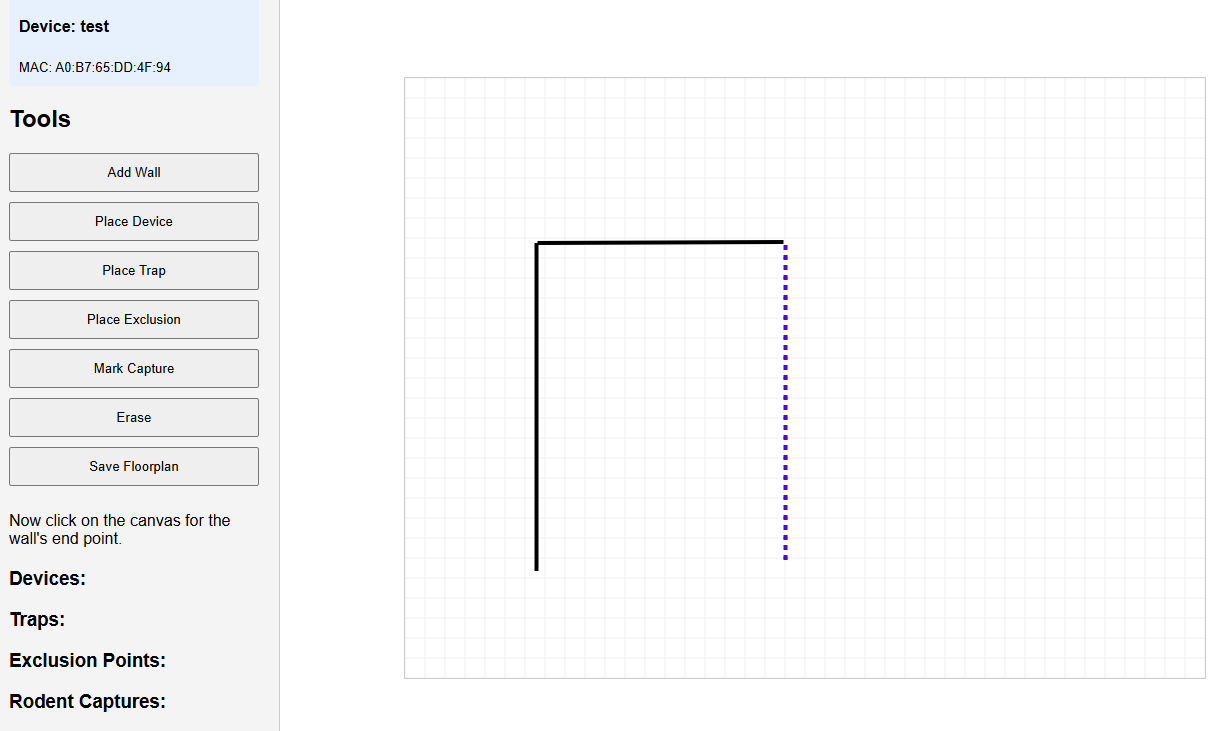

PCB evolution: Development board integration (left) to fully integrated custom design (right)

Manufacturing infrastructure: Custom programming and assembly jig streamlining production workflow

Strategic Two-Stage PCB Approach

Risk Mitigation Strategy: Rather than jumping directly to full custom design, we implemented a conservative progression:

PCB Version 1: Conservative Integration

- Mount existing development board onto PCB

- Maintain proven functionality

- Reduce assembly complexity

- Test PCB manufacturing process

PCB Version 2: Full Custom Design

- Extract processor from dev board

- Build all supporting circuitry on PCB

- Optimize for size and cost

- Complete manufacturing solution

Manufacturing Infrastructure Development:

Version 1 PCB Achievements:

Version 2 PCB Breakthroughs:

Business Model Validation

Critical Achievement: PCB manufacturing provided accurate cost-per-unit analysis for the first time

- Pricing Strategy: Real manufacturing costs enabled competitive pricing

- Volume Economics: Understanding of scale benefits and break-even points

- Investment Planning: Accurate data for business case development

- Market Positioning: Cost structure supporting professional market pricing

Production Capability Transformation:

Manufacturing Lessons Learned

Conservative Progression: Two-stage approach reduced technical risk while enabling learning

Jig Investment: Upfront tooling costs paid back quickly through assembly efficiency

Quality Systems: Consistent processes more important than individual craftsmanship

Cost Transparency: Real manufacturing data essential for business viability

Customer Impact Benefits:

Manufacturing Readiness Achieved

Production Capability: Transition from prototype workshop to professional manufacturing

Business Viability: Accurate cost structure enabling competitive market pricing

Quality Assurance: Consistent, reliable products for enterprise deployments

Scalability Foundation: Infrastructure ready for rapid volume increases

Next Challenge Identified

Manufacturing capability created operational demands: "We need remote management and update capabilities for deployed devices."

Volume deployments required sophisticated device management and over-the-air update systems.

Phase 8: Remote Management & Platform Integration

Operational Transformation: With stable software and PCB manufacturing established, RodentRadar was ready for integration into the comprehensive DuoCore hardware management platform.

Enterprise Requirement: Volume deployments demanded remote management capabilities - devices scattered across multiple locations needed centralized control and updates.

Operational Scaling Challenge

Volume Deployment Reality: Success created logistical challenges

- Dozens of devices per customer installation

- Multiple customer sites across wide geographic areas

- Frequent software improvements and bug fixes

- Need for proactive device health monitoring

Manual Management Crisis: Physical device retrieval for updates was completely impractical at scale

DuoCore Platform Integration Benefits

Rather than building custom management infrastructure, RodentRadar leveraged the mature DuoCore hardware platform:

- Proven Infrastructure: Battle-tested across multiple hardware projects

- Shared Development Costs: Platform improvements benefit all 36in36 projects

- Cross-Project Learning: Management features refined by diverse project needs

- Rapid Integration: Existing APIs and workflows accelerate deployment

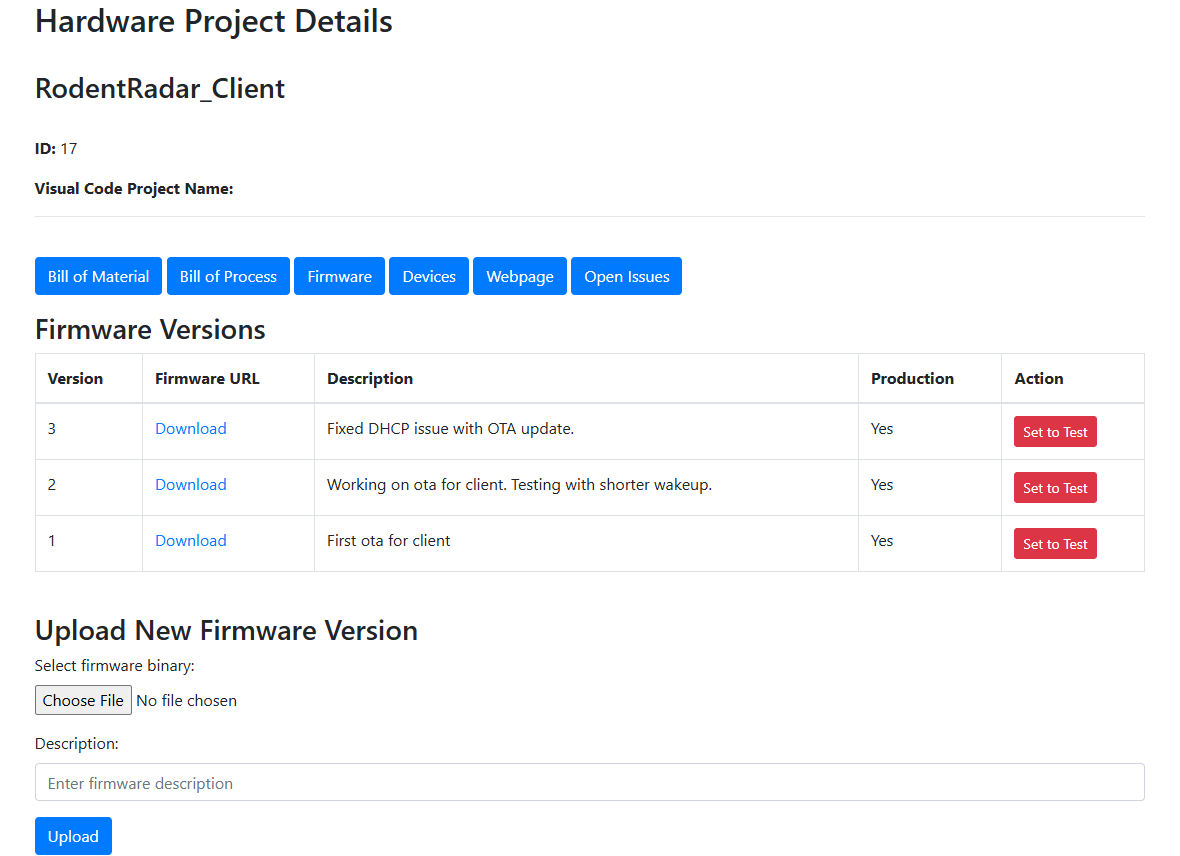

DuoCore platform interface: Comprehensive device management, OTA updates, and remote monitoring capabilities

Simplified Network Architecture

Customer-Friendly Setup: DuoCore platform includes intuitive local provisioning

Base Device Network Setup

- Simple web interface for WiFi configuration

- One-time setup per installation

- No IT expertise required

- Automatic connection management

Sensor Network Simplicity

- Sensors connect only to base device

- No individual network configuration

- Automatic sensor discovery and pairing

- Simplified troubleshooting

Over-the-Air Update Capabilities:

Proactive Device Health Monitoring

Comprehensive Telemetry: Real-time visibility into device status across entire deployment

Battery & Power

- Real-time battery level monitoring

- Power consumption trend analysis

- Low battery proactive alerts

- Charging cycle optimization

Connectivity & Performance

- Signal strength monitoring

- Data transmission success rates

- Device responsiveness metrics

- Network connectivity diagnostics

Operational Revolution

BEFORE OTA

- Physical device retrieval

- Manual firmware updates

- Days/weeks for deployment

- Reactive customer support

AFTER OTA

- Complete remote management

- Automatic updates

- Minutes for global updates

- Proactive issue prevention

Enterprise Deployment Benefits:

Customer Experience Transformation:

Scalability Achievement

Infrastructure Capability: Platform can manage hundreds or thousands of deployed devices from central location

Operational Efficiency: Single administrator can oversee entire deployed fleet

Cost Structure: Remote management eliminates field service costs for updates and maintenance

Market Enablement: Operational scalability supports rapid business growth

DuoCore Ecosystem Value

Platform Benefits: RodentRadar gains enterprise-grade management capabilities without custom development

Shared Innovation: Platform improvements from other projects benefit RodentRadar automatically

Cross-Project Synergies: Management interface optimized by diverse hardware project requirements

Development Efficiency: Focus on core product features rather than infrastructure development

Enterprise Operations Readiness

Remote Management Mastery: Complete operational control without geographic limitations

Proactive Service Model: Issues prevented rather than reactively addressed

Scalable Infrastructure: Platform ready for rapid deployment expansion

Professional Credibility: Enterprise-grade management capabilities competitive with major IoT platforms

Next Challenge Identified

Remote management success revealed field operation needs: "Exterminators need devices that stay in place for continuous monitoring."

Professional workflow requirements demanded rethinking of battery architecture for field serviceability.

Phase 9: Professional Workflow Battery Revolution

Professional Reality Check: Early exterminator feedback revealed a critical workflow requirement - devices must remain in exact positions for continuous behavior analysis, not be removed for charging.

Design Philosophy Shift: From integrated rechargeable devices to user-replaceable battery systems, enabling field serviceability without disrupting monitoring continuity.

Professional Use Case Revelation

Exterminator Workflow Critical Insight: Tracking rodent behavior changes after exclusion work requires consistent device positioning and continuous data from the same sensor over time.

The Professional Question: "Did the sealing work?" "Are they finding new entry routes?" "How has activity changed?"

Data Requirement: Uninterrupted monitoring from identical sensor location to validate intervention effectiveness.

Original Design Flaw

ORIGINAL CONCEPT

Remove device → charge → return

Disrupts continuous monitoringPROFESSIONAL REALITY

Device must stay in exact position

Continuous data essential

Original Design: Large integrated battery

New Design: Compact replaceable battery

Customer-Centric Design Decision

Two Possible Solutions:

- Complex Software Solution: Modify reporting system to track device swaps and maintain data continuity across multiple devices

- Simple Hardware Solution: Replaceable battery system - device stays put, only battery swapped

Chosen Approach: Adapt our system to professional workflow rather than forcing technicians to adapt to our system complexity.

Professional Workflow Analysis:

Replaceable Battery System Benefits

Operational Benefits

- Device remains in exact position

- Continuous data stream maintained

- Quick 30-second battery swap

- No recalibration required

Technician Benefits

- Minimal workflow disruption

- No device tracking complexity

- Simple field maintenance

- Reduced service time per location

Unexpected Engineering Benefits:

Manufacturing Impact

Unexpected Benefit: Compact battery design reduced overall device footprint

ORIGINAL

Larger Housing

More printing timeNEW DESIGN

Compact Housing

Faster productionProfessional Value Demonstration:

Customer Workflow Integration:

Design Philosophy Learning

User-Centric Approach: Best engineering solutions adapt to user workflows, not vice versa

Professional Requirements: Real user feedback reveals requirements not obvious in lab testing

Simplicity Wins: Hardware solution often better than software complexity

Secondary Benefits: User-focused design improvements often create unexpected advantages

Professional Workflow Mastery

Continuous Monitoring: Uninterrupted data collection for professional analysis

Field Serviceability: Simple maintenance without disrupting operations

Manufacturing Efficiency: Compact design reduces production time and cost

Professional Credibility: System designed around real exterminator workflow requirements

Next Challenge Identified

Professional deployment success revealed infrastructure needs: "We need better communication range and reliability across different building types."

Real-world deployment environments demanded comprehensive antenna optimization and range testing.

Phase 10: Communication Infrastructure Mastery

Foundation Infrastructure Challenge: Ensuring reliable communication across various building types, materials, and distances was critical for professional deployment success.

Significant Engineering Investment: Comprehensive time investment in both processor antenna selection and base device antenna optimization to maximize sensor placement flexibility.

Real-World Deployment Challenges

Building Complexity Factors:

- Construction Materials: Concrete, steel, brick walls affecting signal penetration

- Facility Layouts: Long corridors, multiple floors, complex floor plans

- Environmental Interference: Other wireless devices, electrical equipment

- Distance Requirements: Large facilities demanding extended communication range

Professional Requirement: Reliable operation regardless of building constraints

Dual Antenna Optimization Strategy

Comprehensive Approach: Significant engineering time invested in optimizing both ends of the communication link

Processor Antenna Selection

- Extensive research and testing

- Balance size, power, and performance

- Sensor device constraints consideration

- Multiple antenna technologies evaluated

Base Device Antenna Enhancement

- Dedicated antenna system added

- Range and reliability optimization

- Professional appearance maintained

- Signal strength maximization

First customer-acceptable version: Base device with visible antenna for enhanced range and LED status indicators for user feedback

Range Extension Achievement

BEFORE

Limited Range

Constrained sensor placementAFTER

Extended Range

Flexible sensor positioningBase device antenna greatly improves sensor placement distances

Comprehensive Testing Methodology:

Customer-Ready Design Features:

Engineering Time Investment

Significant Commitment: Substantial time spent on antenna optimization demonstrates commitment to robust, reliable field performance

Foundation Priority: Understanding that poor communication undermines all other sophisticated capabilities

Professional Standards: Meeting enterprise-grade reliability requirements for commercial deployment

Real-World Deployment Benefits:

Commercial Environment Validation:

Infrastructure Philosophy

Foundation First: Reliable communication is prerequisite for all advanced features

User Experience Impact: Poor signal strength creates customer frustration regardless of software sophistication

Professional Credibility: Enterprise customers expect robust, reliable infrastructure performance

Competitive Advantage: Superior range and reliability differentiates from basic sensor solutions

LED Status System Benefits:

Communication Infrastructure Mastery

Extended Range Capability: Sensor placement flexibility maximized for optimal detection positioning

Professional Reliability: Consistent performance across diverse commercial building environments

Customer-Ready Design: Professional appearance with clear operational status indication

Deployment Simplification: Reduced infrastructure requirements for comprehensive facility coverage

Next Challenge Identified

Reliable communication infrastructure enabled focus on user experience: "Customers need simpler setup and device management procedures."

Professional deployment success revealed the importance of streamlined customer workflow integration.

Phase 11: Intuitive User Experience Revolution

User Experience Crisis: Technical success meant nothing if customers couldn't easily set up and manage devices. Complex procedures were killing adoption and creating support burden.

Professional Mobility Challenge: Exterminators needed seamless device transport between different job sites across town, requiring completely streamlined setup processes.

User Experience Barriers

Setup Complexity Issues:

- Complex device activation procedures

- Confusing sensor identification and placement

- Battery life uncertainty during shipping and storage

- Time-consuming setup for each new location

Professional Impact: Exterminators losing billable time on technology setup instead of pest control work

Shipping Mode Innovation

Battery Preservation Strategy: Devices ship in low-power "shipping mode" preserving battery capacity during storage and transport

Activation Simplicity: Single intuitive action transforms device from shipping mode to active detection mode

Customer Benefit: Devices arrive with maximum battery life, ready for immediate extended deployment

Intuitive activation system: Small round disc on base device top for sensor wake-up, with LED feedback confirming successful activation

Revolutionary Wake-Up System

Activation Method: Sensor device swiped over small round disc on top of base device

Instant Transformation: Device awakens from shipping mode to ready-to-detect state

Visual Confirmation: LEDs immediately provide feedback confirming successful activation

Professional Workflow: Eliminates complex setup procedures for multi-location deployments

LED Feedback System

Two White Flashes

Sensor activation detected

Two Green Flashes

Sensor ready for placement

Visible on both customer dashboard AND base device LEDs

Professional Multi-Location Workflow:

Alphabetical Organization System

Sensor Labeling: Each sensor clearly labeled with letter (A, B, C, etc.)

Physical Placement Guide: Technicians and property owners place sensors in alphabetical order

Digital Interface Matching: Floorplan interface displays sensors in same alphabetical sequence

Intuitive Correlation: Perfect match between physical placement and digital representation

Floorplan Integration Benefits:

Error Prevention & User Confidence:

Complete User Journey Optimization

Shipping to Setup Pipeline:

- Factory: Device ships in low-power mode with maximum battery

- Transport: Minimal power drain during shipping and storage

- Arrival: Customer receives device ready for extended deployment

- Activation: Single swipe transforms to active detection mode

- Deployment: Alphabetical placement with digital interface correlation

- Operation: Immediate productive monitoring begins

Professional Workflow Integration:

User Experience Design Philosophy

Invisible Complexity: Sophisticated technology hidden behind simple interactions

Professional Respect: Technology adapts to professional workflows, not vice versa

Error Elimination: Design prevents mistakes rather than relying on user training

Immediate Feedback: Visual confirmation builds user confidence and prevents uncertainty

Business Impact Transformation:

User Experience Mastery Achievement

Intuitive Activation: Single swipe transforms shipping mode to operational readiness

Visual Feedback System: LED confirmation eliminates setup uncertainty and builds confidence

Professional Workflow Integration: Multi-location deployment without complexity or reconfiguration

Error-Resistant Design: Alphabetical organization and visual feedback prevent common mistakes

Battery Optimization: Maximum deployment time through intelligent shipping mode preservation

Market Ready Achievement

User experience optimization completed the transformation from technical prototype to market-ready professional solution. RodentRadar now offered enterprise-grade detection capabilities with consumer-grade simplicity.

Ready for Scale: All technical, operational, and user experience challenges addressed for rapid market expansion.

Market Validation: Organic Discovery Success

Encouraging Organic Discovery: Posted rodentradar.com with no promotional activities, yet seeing meaningful organic discovery by people actively seeking monitoring solutions.

Professional Market Validation: Early contact from large Southern California exterminator specifically requesting "24x7 monitoring system for their customers."

Genuine Market Demand

Baseline Reality: Most development websites receive zero traffic before promotion

RodentRadar Discovery: Multiple visitors finding the site through active searches for monitoring solutions

Market Signal: People are actively looking for exactly what we built

Professional Market Validation

Contact: Large exterminator company in Southern California

Request: "24x7 monitoring system for their customers"

Significance: Professional service provider seeking exactly what RodentRadar provides

Market Fit: Direct alignment with core value proposition

Market Readiness Indicators:

Ready for Growth

Organic discovery by both end customers and professional service providers suggests strong market readiness for proactive rodent monitoring solutions, supporting the timing for broader marketing and sales efforts.

Current State: Proven Technology Foundation

From basic communication proof-of-concept to comprehensive IoT solution with validated detection capabilities, visual analytics, and professional deployment features. While we have a long way to go, continued methodical improvement positions us for market success.